Guide to Maintaining Retractable Ratchet Straps

Keep your cargo secure with your retractable tie-downs’ proper maintenance and storage techniques.

I have been hauling gear long enough to know one thing for sure: your straps are either your best friend on the road, or your biggest headache when they fail. Retractable ratchet straps, those self-winding tie-downs, are some of the handiest tools you can own. No tangles, no wrestling with loose webbing. But here’s the deal: if you don’t take care of them, they are gonna wear out quicker than you think.

And trust me, the last thing you want is a strap giving out when you are hauling a dirt bike, a load of lumber, or the family’s camping gear down the highway. A little maintenance goes a long way toward keeping your cargo safe and your straps working like they should. Here’s my no-BS guide to keeping retractable ratchet straps in top shape:

Read more: Ultimate Guide to Retractable Ratchet Straps (2025 Edition)

Storage

#1 Avoid moisture

- Choose a dry storage area. A humid environment can lead to mold growth, weakening the webbing and potentially causing damage.

- Opt for a well-ventilated space. The storage area should have good airflow to prevent the buildup of moisture.

- Store them away from areas prone to moisture. Excessive exposure to heavy rain or high humidity over time can promote mold formation on your ratchet straps.

#2 Shield from Heat

- Keep away from heat sources. Direct contact with fire and other intense heat sources can weaken tie-downs’ webbing.

- Avoid direct sunlight. Long exposure can damage the webbing. Choose a shaded spot to protect the straps from the sun and help keep to preserve the straps’ integrity.

#3 Separate from sharp stuff

- During transportation and storage, avoid any rubbing or friction of the webbing against sharp edges or other objects. Friction can weaken the straps, creating weak spots and visible defects.

- Properly secure and position your cargo to avoid unnecessary rubbing against the straps during transportation.

#4 Use a bag or box

- Use designated storage containers or bags. A dedicated drawer or toolbox can keep your tie-downs neatly organized.

- Separate from other tools and equipment. Store the straps separately from other tools or equipment to avoid potential damage.

#5 Check on your straps regularly

- Inspect your straps regularly. Even in storage, perform regular inspections to check for signs of wear, damage, or deterioration.

- Look for frayed edges, cuts, or weakened spots that may compromise their strength and reliability.

- Replace damaged straps right away for safety and reliability.

Tip: Don’t always use the same two straps for every job. Rotating them helps spread out the wear and extends their overall lifespan.

Maintenance and Fix

#1 Clean the straps after use

After a trip, it’s pretty common for your straps to pick up dirt, dust, or even a little grease. If you don’t clean them, that buildup can wear down the webbing and mess with the retraction spring over time.

The fix is simple: use a bit of mild soap and warm water with a soft cloth. Wipe the straps clean, rinse them off, and let them air dry before retracting. Just avoid harsh chemicals or scrubbing with anything rough because those can weaken the fibers.

Tip: If you’re hauling in winter, rinse straps after exposure to road salt. Same goes for chemicals like fuel or oil because they can eat into the fibers and weaken the strap.

#2 Inspect for damage

Before you strap anything down, give your gear a quick once-over. Look at the webbing for frays, cuts, or spots that look worn out. Even small weak points can turn into a bigger problem when the strap’s under load.

Don’t forget the ratchet itself! Make sure the handle moves smoothly and nothing feels loose or jammed. If something looks off, it’s better to swap out the strap (or the part) than risk a failure on the road.

Tip: Even with good care, straps can fail. Keeping a spare set in your truck or trailer means you are never stranded without tie-downs.

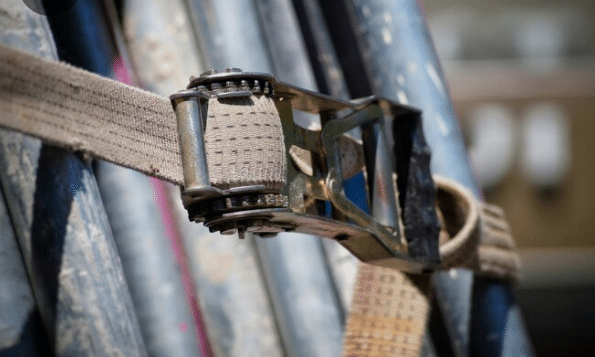

#3 Lubricate the ratchet mechanism

Every now and then, your ratchet might start feeling a little stiff or squeaky. That’s your cue to hit it with some lube. Apply it on the parts as shown in the picture above! By the way, a silicone-based spray works best. You can find it at just about any hardware store. Go easy with it, though. A quick shot on the gears is usually all it takes to keep things moving smoothly. Too much and you’ll just end up with a greasy mess.

Also, avoid WD-40 for long-term fixes. It’s fine in a pinch, but it evaporates quickly and can leave the mechanism dry again. Stick with silicone or a light machine oil for lasting smoothness.

Tip: If dirt or grit is jammed in the gears, spray it out or wipe it down before adding lubricant. Otherwise, you’re just trapping the grime inside.

#4 Avoid overloading

Retractable straps are tough, but they aren’t indestructible. Pushing them past their limits can wear them out fast, or worse, cause them to snap when you need them most.

Make sure you are using straps with the right working load limit (WLL) and breaking strength for the job. Check the tag, do the math, and don’t cut corners. Spread the weight out evenly, too. A balanced load rides safer and keeps your straps from taking all the stress in one spot.

Read more: A Detailed Guide to Breaking Strength vs Working Load Limit

The Takeaway

Remember to clean the straps after each use, inspect them for damage, lubricate the ratchet mechanism, store them properly, and avoid overloading. Take care of your retractable tie-downs to keep your cargo secure. Happy hauling!

—

Ready to upgrade your cargo-securing game? Visit strapinno.com/shop/ today and discover high-quality, reliable, durable tie-downs that revolutionize your hauling experience. Don’t settle for subpar equipment when it comes to securing your valuable cargo. Your cargo deserves the best!